Technical information

1. Full port ball valve, Wafer type

2. Assembly with flanges DIN EN PN16

3. Made of Stainless Steel AISI 316

4. Ball seats PTFE + 15% G.F.

5. Blow - out proof stem

6. Direct mounting actuator according ISO 5211 (from 1”)

7. Block System included

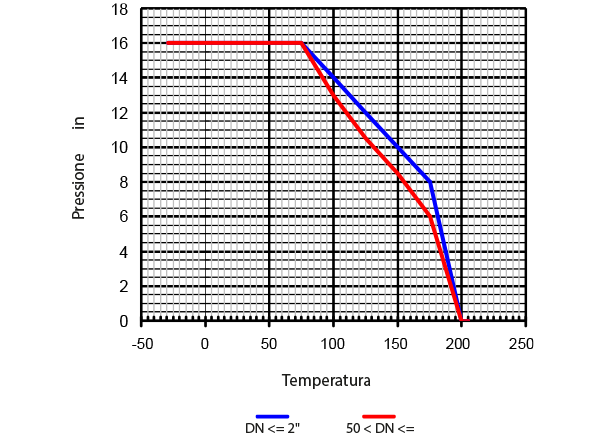

8. Max. Working pressure 16 bar

9. Working Temperature -20°C + 180°C

Technical information

1. Full port ball valve, Wafer type

2. Assembly with flanges DIN EN PN16

3. Made of Stainless Steel AISI 316

4. Ball seats PTFE + 15% G.F.

5. Blow - out proof stem

6. Direct mounting actuator according ISO 5211 (from 1”)

7. Block System included

8. Max. Working pressure 16 bar

9. Working Temperature -20°C + 180°C

|

N° |

Nome Name |

Materiale Material |

Finitura Superficiale Surface Treatment |

|

1 |

Corpo / Body |

Inox Aisi 316 |

Sabbiata / Shoot blasting |

|

2 |

Coperchio / Cap |

Inox Aisi 316 |

Sabbiata / Shoot blasting |

|

3 |

Guarnizione corpo / Gasket |

PTFE |

--- |

|

4 |

Sfera / Ball |

Inox Aisi 316 |

--- |

|

5 |

Guarnzione sede / Ball |

PTFE + 15% GF |

--- |

|

6 |

Sfera stelo / Stem |

Inox Aisi 316 |

--- |

|

7 |

Rondella / Trust washe |

PTFE |

--- |

|

8 |

O’ring / O’ring |

VITON |

--- |

|

9 |

Guarnizione corpo / Stem packing |

PTFE |

--- |

|

10 |

Guarnizione / Stem ring |

Inox Aisi 304 |

--- |

|

11 |

Dado / Nut |

Inox Aisi 304 |

--- |

|

12 |

Rondella molla / Spring Washer |

Inox Aisi 304 |

--- |

|

13 |

Rosetta anti slittamento / Lock washer |

Inox Aisi 304 |

--- |

|

14 |

Rondella / Washer |

Inox Aisi 304 |

--- |

|

15 |

Fermo spilla / Stop pin |

Inox Aisi 304 |

--- |

|

16 |

Leva / Handle |

Inox Aisi 304 |

--- |

|

17 |

Coperchio plastica / Plastic cover |

VINILE / VYNIL |

--- |

|

Diametri Size |

Codice Code |

PN |

Dimensioni / Dimensions (mm) |

Fori Holes |

Peso Weight (Kg) |

|||||||

|

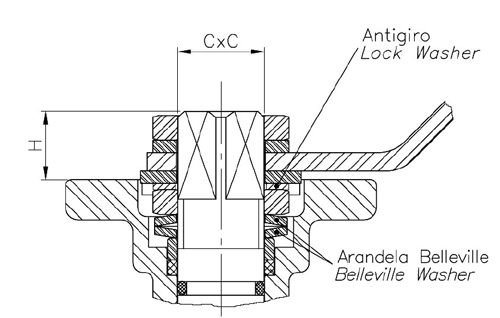

ø d |

A |

L |

M |

ISO 5211 |

H |

CxC |

||||||

|

1/2” |

IV1181/2 |

16 |

95 |

85 |

36 |

115 |

F03 |

F04 |

10 |

9x9 |

4xM12 |

1.70 |

|

3/4” |

IV1183/4 |

16 |

105 |

90 |

38 |

115 |

F03 |

F04 |

10 |

9x9 |

4xM12 |

1.90 |

|

1 ” |

IV1181 |

16 |

115 |

95 |

50 |

170 |

F04 |

F05 |

10 |

11x11 |

4xM12 |

2.50 |

|

1 1/4” |

IV11811/4 |

16 |

140 |

100 |

53 |

170 |

F04 |

F05 |

12.5 |

11x11 |

4xM16 |

3.50 |

|

1 1/2” |

IV11811/2 |

16 |

150 |

105 |

65 |

210 |

F05 |

F07 |

14.5 |

14x14 |

4xM16 |

4.35 |

|

2 ” |

IV1182 |

16 |

165 |

115 |

78 |

210 |

F05 |

F07 |

14 |

14x14 |

4xM16 |

5.45 |

|

2 1/2” |

IV11821/2 |

16 |

185 |

130 |

98 |

260 |

F07 |

F10 |

17 |

17x17 |

4xM16 |

7.80 |

|

3” |

IV1183 |

16 |

200 |

145 |

118 |

260 |

F07 |

F10 |

16 |

17x17 |

8xM16 |

10.30 |

|

4” |

IV1184 |

16 |

220 |

175 |

140 |

260 |

F07 |

F10 |

19 |

17x17 |

8xM16 |

18.00 |

|

Misura Size |

Coppia Activating torque (Nm) |

|

DN15 |

4 - 5 |

|

DN20 |

6 - 8 |

|

DN25 |

8 - 10 |

|

DN32 |

12 - 14 |

|

DN40 |

18 - 20 |

|

DN50 |

25 - 30 |

|

DN65 |

32 - 36 |

|

DN80 |

50 - 60 |

|

DN100 |

85 - 95 |

|

1/2" |

3/4" |

1" |

1 1/4" |

1 1/2" |

2" |

2 1/2" |

3" |

4" |

|

24 |

43 |

83 |

130 |

205 |

340 |

520 |

1100 |

1820 |